Belt Alignment

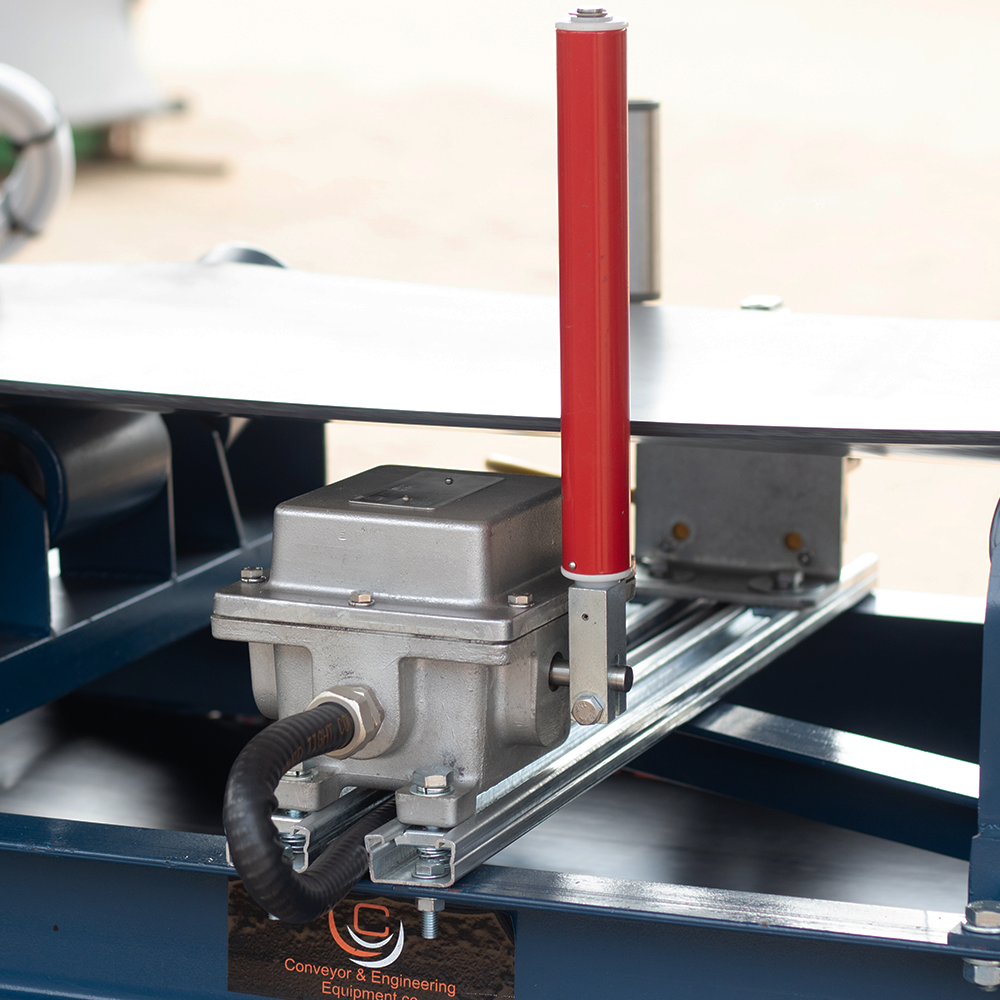

Conveyor Belt Alignment switches are mounted on sections of plant conveyors to protect against excessive belt drift due to an unintentional movement. They can be fitted at appropriate points along the conveyor length to ensure that should the belt position drift, the roller arm of the switch will move to a pre-determined position and cause activation of a control circuit.

Each standard sized belt alignment switch contains two sets of contacts, one which indicates a warning signal (for maintenance purposes) and the other a stop signal, disconnecting the outputs and stopping the belt.

WHY IS IT NECESSARY? The Model TA is relatively inexpensive protection that provides benefit by saving the time, money, and labor associated with replacing a damaged conveyor belt.